Cleaning up Keystone spill to cost $480 million, says TC Energy

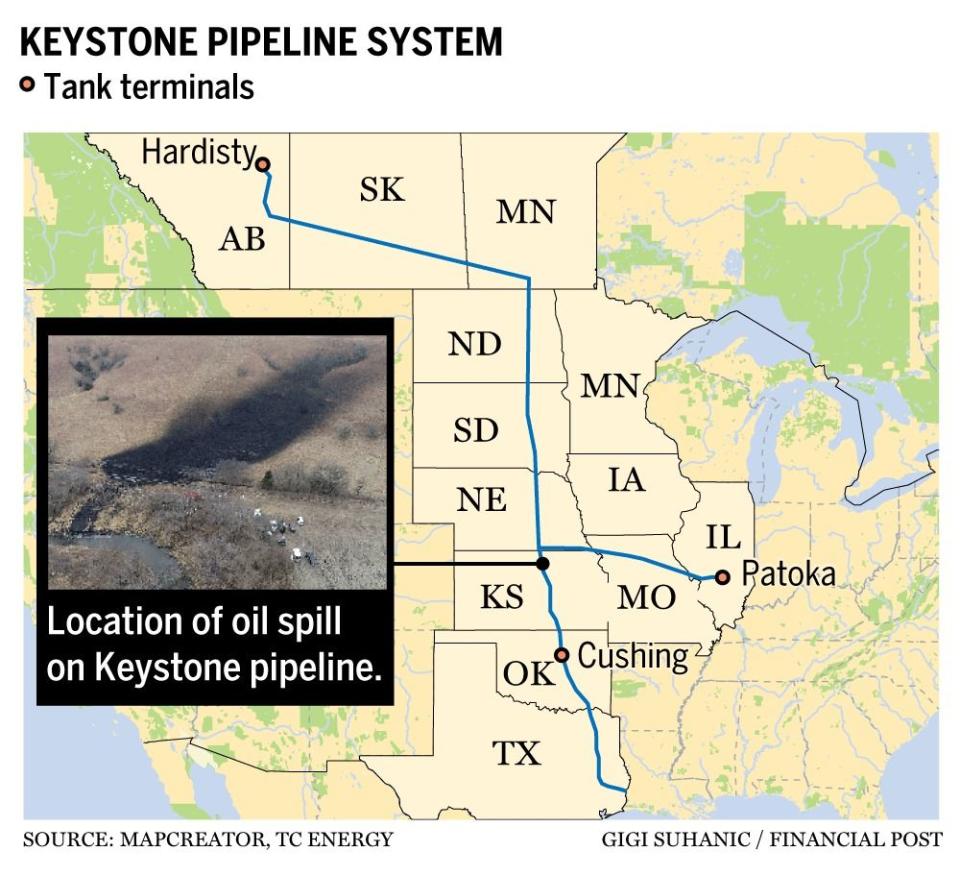

TC Energy Corp. says cleanup of a massive crude spill from its Keystone Pipeline into a creek in Kansas last December will cost US$480 million.

The Calgary-based company announced Feb. 9 that a third-party analysis into what caused the leak is still underway, but it has been determined that the spill on Dec. 7 occurred because of a combination of factors, including “bending stress” on the pipe and a weld flaw attributed to work completed at a fabrication facility.

The update included a revised figure for the volume of the spill in Washington County, Kansas. The company said 12,937 barrels of crude oil were released in the rupture along Mill Creek; previously TC Energy had estimated 14,000 barrels.

“Although welding inspection and testing were conducted within applicable codes and standards, the weld flaw led to a crack that propagated over time as a result of bending stress fatigue, eventually leading to an instantaneous rupture,” the company said in a release.

“The cause of the bending stress remains under investigation as part of the broader third-party root cause failure analysis.”

The company said a metallurgical analysis identified no issues with the strength or material properties of the pipe or manufactured fitting. “The pipeline was operating within its operational design and within the pipeline design maximum operating pressure,” it said.

The spill, which prompted a nearly month-long shutdown of the critical cross-border pipeline, will cost the company an estimated US$480 million for investigation and remediation work. The company said it was working with insurers to maximize cost recoveries.

Keystone, which carries crude 4,324 kilometres from Alberta to refineries in Oklahoma and the U.S. Gulf Coast, was granted a special permit in 2017 enabling it to operate in the U.S. at a higher stress level than is otherwise allowed under federal pipeline regulations.

The special permit process is currently the subject of an independent review launched by the U.S. federal pipeline regulator in response to concerns raised about Keystone’s safety in a 2021 U.S. Government Accountability Office report.

“A bad weld from a fabrication facility is troubling – it adds to the list of manufacturing and construction issues that have plagued this pipeline,” Bill Caram, executive director of Pipeline Safety Trust, a U.S. advocacy group against pipeline hazards, told Reuters.

Land movement likely caused a bad weld to break and bending stress on the pipe, said Caram, adding that Keystone’s permit requires it to mitigate such threats.

Canada does not have a special permitting system for its pipelines crossing inter-provincial or international boundaries. Each Canadian pipeline is certified to a particular maximum operating threshold, according to the Canada Energy Regulator (CER).

TC Energy’s Keystone pipeline may be ‘unsaleable’ this year due to spill, analyst says

TC Energy’s troubles mount as Keystone spill remains unexplained after five days

U.S. pipeline regulator launched review of special permit process following audit of Keystone spills

TC Energy has voluntarily reduced operating pressure across the entire Keystone line since flows resumed at the end of December.

“Our focus continues to be the safe operation of the pipeline system,” the company said. “Additional operational mitigations, such as reduced operating pressure, are in place to support the safe operations of our system while we continue our response and investigation. Our team is progressing a remediation plan, including an analysis of other areas with potentially similar conditions, the use of additional in-line inspections, and further operational mitigations.”

Additional reporting by Reuters

• Email: mpotkins@postmedia.com | Twitter: mpotkins

Yahoo Finance

Yahoo Finance