Electrification Might Be the Answer to the Turbocharger's Biggest Problem

From the June 2018 issue

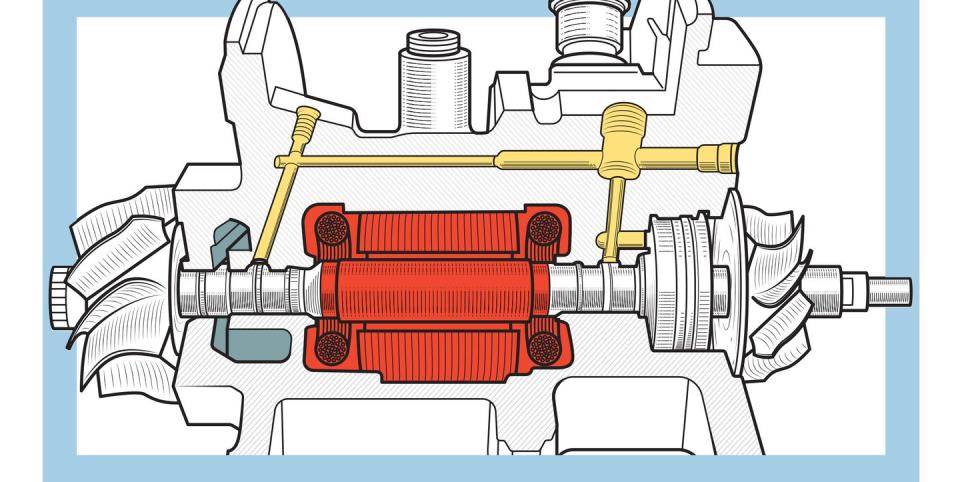

Turbo engines are better now than they’ve ever been. But they are about to become awesome. Most contemporary turbo mills use a turbocharger sized to produce ample torque at low engine speeds. This sizing constricts the turbine wheel and housing, which creates significant exhaust backpressure at high engine speeds. High backpressure increases an engine’s tendency to detonate, a problem engine calibrators, until now, often fixed by running richer air-fuel ratios. This strategy increases fuel consumption and emissions. And while using a bigger turbo allows for decreased backpressure, it also results in too much turbo lag. Usefully inserting itself into this dilemma-as well as the space between the turbo’s turbine and compressor-is electricity. With an electric motor/generator in the water-cooled and oil-lubricated center housing, so-called e-turbos should allow the use of bigger turbines for high-end power while filling in the bottom of the rev range with electrically driven boost.

Depending on load conditions, the e-turbo’s motor/generator can either increase boost by supplementing exhaust energy to drive the compressor wheel or act as a gas-driven generator to turn exhaust energy into electricity that can be stored for later use. Because of their power demands-about seven horsepower on current passenger-car prototypes-electric turbos will initially pair with existing 48-volt hybrid powertrains, which also use a belt alternator/starter or motor/generator to add torque to the wheels and recuperate electrical energy during braking. The powertrain controller will decide among the various options for generating and spending power depending on the requested torque, use scenario, and safety and reliability constraints of the system.

Currently, only one production car on the planet-Mercedes-AMG’s Project One supercar-uses an electric turbocharger. The Project One derives its powertrain from the Mercedes-AMG Formula 1 car, and both navigate the cutting edge of gas-electric automotive technology. But a Formula 1 powertrain is hardly the thing to make the e-turbo relevant to the masses. Rather, it’s what the electric turbocharger enables-the efficiencies that it unlocks-that will make it matter in 2020 or 2021, when it will likely appear in more-modest performance cars.

According to Rob Cadle, engineering director and electrification business leader at Honeywell, every kilowatt of electricity used to drive the turbo translates to about 10 kilowatts (13 horsepower) of output at the crankshaft. Of course, it’s not a free lunch-there’s a fuel-economy penalty for making more power with the combustion engine.

But the benefits are numerous for early-adopting automakers that will use e-turbos primarily as performance enhancers, pairing a relatively large turbo with a small engine. Additionally, the e-turbo shows promise as an enabler of more power and better fuel economy by allowing nearly stoichiometric (chemically complete air-fuel) combustion at higher boost rather than the rich air-fuel ratios often used with turbo engines today.

The e-turbo’s ability to recuperate power is what sets it apart from the electric supercharger. Both devices use electrical power to fill in the bottom part of the powerband before exhaust energy fully takes over, but because an e-turbo can add electrical power back into the system, its appeal to automakers contending with CO2 regulations and Corporate Average Fuel Economy standards is ultimately greater.

E-turbos generate electricity in two different scenarios. The first occurs in no-load conditions when the turbo’s rotating assembly would normally slow on its own. The second scenario is more clever. By opening the wastegate later or with a smaller opening than would happen in a conventional turbo, the electric turbo uses exhaust energy to simultaneously create boost for the engine and generate electrical power. Again, it’s not a something-for-nothing proposition. On-boost electricity generation increases exhaust backpressure. But, says Cadle, there’s a sweet spot where the energy extracted from the e-turbo during this type of regeneration is higher than the penalty paid in fuel economy and CO2 emissions.

On passenger-car engines, e-turbos are not yet fully proven as net-zero energy devices-ones that produce as much power as they consume. Even if that’s not the case, they will contribute to a hybrid system that delivers more power and better fuel economy than was available without them.

You Might Also Like

Yahoo Finance

Yahoo Finance