Do We Really Want 3D-Printed Food?

Hod Lipson's laboratory at Columbia University is a place designed to nurture the human instinct to tinker. The space itself is pretty basic: linoleum floor, white walls, natural wood tables. Wires, markers, textbooks, and glue bottles cover most surfaces-the detritus of students designing, making, refining, and tweaking. Robotic models line the shelves: a robot with foot-long plastic wings that look like a housefly's, miniature machines with exposed silver gears, geometric robotic skeletons. There are laser cutters and microscopes and welding masks hung on hooks. Pushed up against a wall, a robotic arm bears a paper sign: "DANGER. Robot moves without warning. KEEP AWAY."

Lipson became a professor of mechanical engineering at Columbia in 2015, after fourteen years as a professor at Cornell University. He is a pioneer in the field of three-dimensional printing, and one of the first to experiment with substituting the usual raw materials-plastics, metals-with edible food products. It was in Lipson's lab about ten years ago that a few of his students had the idea to mess around with it. Somebody tried filling a printer syringe with frosting. Then cheese, chocolate, and other foods. "In the beginning we thought it was frivolous," Lipson says. "We'd say 'Look, we printed with chocolate, but let's get serious and do our battery work.' "

But when writers at The New York Times and the BBC started inquiring about the technology, Lipson saw public interest that he hadn't anticipated. People who "couldn't care less about batteries or robotics" suddenly cared about 3D printing when food got involved, he says. Everybody cares about food. A new branch of 3D printing began.

"DANGER. Robot moves without warning. KEEP AWAY."

This is what humans do: We tinker. We improvise. We have weird ideas and mess around with them. It leads to things like the discovery of electricity, and sailboats, and machine guns, and food that comes out of a printer. Lipson is like the rest of us in that sense, it's just that his reflex to act on his curiosity is more acute, more insatiable. We-the more insatiable among us-have now devised technology that influences the way we communicate, travel, work out, sleep, and entertain. Lipson sees these printers as the future of food preparation. There are a handful of startups already building up the industry, but experiments with the technology have also been backed by more venerable organizations-such as Columbia University, NASA, and the European Union.

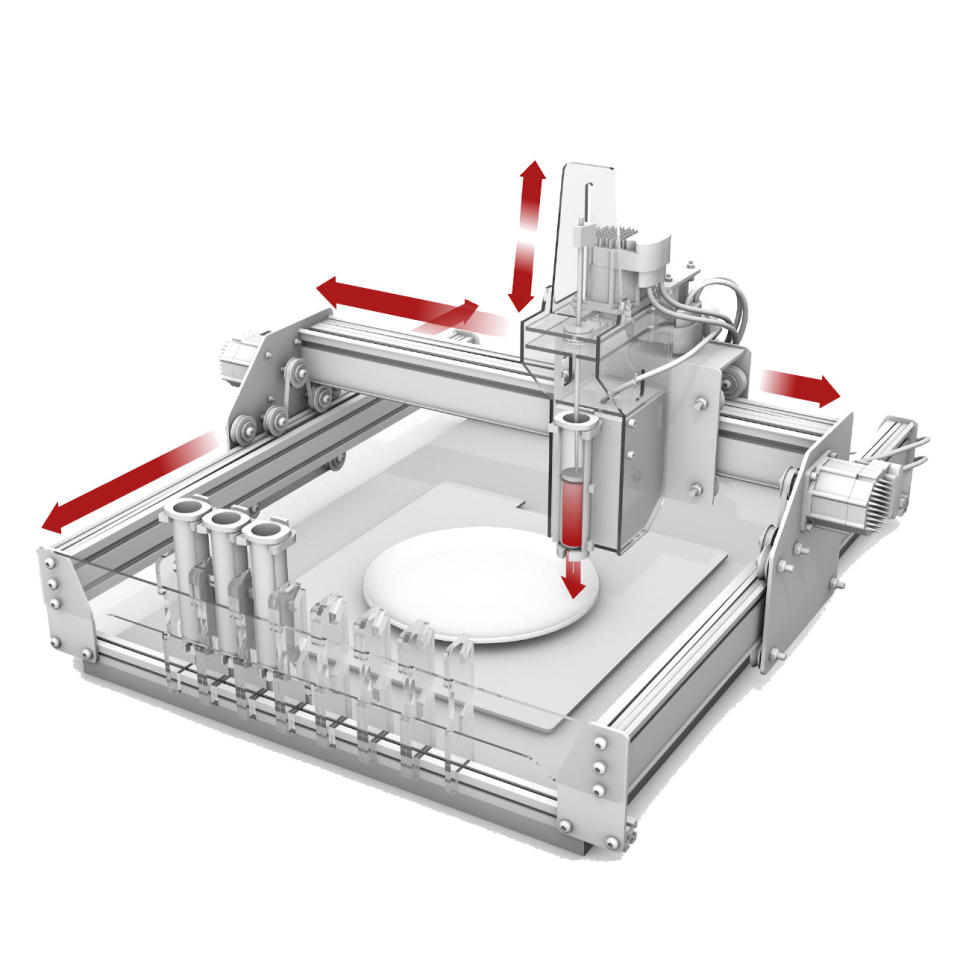

The term "3D printing," of course, is odd. It's desktop manufacturing, and making food this way is no different from making toys or machine parts or anything else 3D printed. Once you place the raw material, in this case an edible paste, into a 3D printer, a robotic arm deposits or spreads the paste in precise layers, forming whatever shape you've programmed into the machine. The better equipped the machine, the more advanced the recipes it can make.

Lipson and his students agree that 3D-printed food will never completely replace our current food system. A printer is unlikely to print a filet mignon and salad anytime soon. But it is likely to become a regular appliance you use-as soon as the next ten years, Lipson says. A machine with multiple material canisters lets you print different flavors or colors into the layers, like a rainbow-striped cake or kale-filled chocolate bars. A laser or infrared light on the nozzle serves as a cooking element, so ingredients cook as they're deposited out of the machine.

Of the few 3D-food printers sold right now, most emphasize novel shapes. The Magic Candy Factory prints big gummy candies in the shapes of octopuses, butterflies, a child's name. The PancakeBot prints two-toned pictures onto a griddle. 3D Systems prints beautiful sugar sculptures, precise geometric shapes that the human hand could never do as perfectly.

"People shrug off this technology and say it's just fun," says Kjeld van Bommel, a research scientist who has worked on candy-printing technology. "But fun is a huge part of food." And all over the world, universities and corporations are experimenting with applications for 3D-printing food beyond amusement. As a senior consultant at the Netherlands Organisation (TNO) for applied scientific research, van Bommel looked into the possibility of using 3D-food printers in nursing homes. For elderly patients who have difficulty chewing, printers would fashion purees into more appealing shapes-carrot puree shaped like real carrots or salmon puree shaped like a real block of fish. The printers could also personalize nutrition in the printed meals, adding things like sunflower oil, whey protein, and minerals. They could produce about twenty personalized meals per hour, and label each individual meal with the exact name and address of nursing-home residents. TNO is now talking to companies interested in taking the experimental technology to commercial production.

NASA also experimented with the technology for Mars missions, since food loses nutritional value over time-even more so in the radiation of space. In 2013 it awarded a Small Business Innovation Research contract to Systems & Materials Research Corporation (SMRC) to develop a 3D-printed food system for astronauts. SMRC successfully printed a pizza, though the project was later abandoned after a senator called it "wasteful government spending." But SMRC is looking into other applications. SMRC president Malcolm Prouty says the Army has shown interest in using the technology to bring customized nutrition to soldiers.

BeeHex, a spin-off of the NASA project, is attempting to turn pizza printers into a franchise to be used at stadiums and other large venues. Chief marketing officer Jordan French says its product could make line cooking faster, cheaper, and less stressful. Lynette Kucsma, cofounder of the Foodini commercial food printer, wants to make foods that people would typically buy in processed form more wholesome. Instead of restaurants serving you flash-frozen burger patties that are full of preservatives, they could efficiently print their own. It's fast and convenient, and your burger wouldn't be full of manufacturing chemicals.

Dozens of other potential uses have been proposed-some imaginative, some outlandish, some brilliant. We could print delicious food out of cheap, sustainable, otherwise unpalatable ingredients, like algae or insect flour. We could develop nutrition trackers and print personalized breakfast bars tailored to our exact nutrition needs. We can take these printers anywhere that's hard to get fresh food to, one of Lipson's students said-into space or submarines, across the world to deserts.

There are limitations to overcome. Right now, printers are slow, use a lot of energy, and require some knowledge to program. Chef Hervé Malivert, director of culinary technology and chef coordinator at the International Culinary Center in New York City, thinks they'll be a hard sell for chefs, who value a variety of textures in their dishes. But we are, by nature, progressive creatures. Ten years after those experiments with frosting and chocolate, new students in Lipson's lab are still experimenting with 3D-printed food, now as serious work. The once frivolous hobby is now the focus of graduate work and theses.

Whether humans decide we want to eat the food paste that comes out of these machines remains to be seen. In a way, that's not the point. This is a moment in the continuum, an early stage in the evolution of whatever this is. People-the more insatiable among us-keep experimenting with what we've got. We keep tinkering. Because that's what we do.

This story appears in the December 2016 / January 2017 issue of Popular Mechanics

You Might Also Like

Yahoo Finance

Yahoo Finance